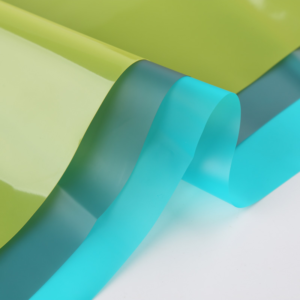

In the production process of fully automatic packaging film, appropriate dimensional tolerance is one of the important factors to ensure stable packaging effect. To ensure the quality of the plastic film, it is necessary to control the thickness tolerance in production. Thickness tolerance is the difference between the measured thickness and the actual thickness, usually expressed as a percentage.

What is the allowable tolerance of plastic film thickness ?

1. The thickness tolerance of single layer plastic film is ≤±3%

2. The thickness tolerance of aluminum foil is ≤±4%

3. The thickness tolerance of composite film is ≤±10%

4. Films with poor thermal stability should have smaller thickness tolerances

5. The thickness tolerance of high-precision films should be smaller

To ensure the accuracy of film manufacturing, some measures need to be taken to reasonably control the thickness tolerance:

1. Use high-precision equipment and materials to improve precision in the plastic film production process

2. Utilize automated production lines to reduce plastic film manufacturing tolerance

3. Detect and solve problems in a timely manner through film quality control and production process monitoring

4. Adopt manufacturing processes and methods that are conducive to controlling thin film tolerances

POLYSAN strictly controls and monitors in accordance with national standards of plastic film when producing and processing. POLYSAN produce and supply high quality plastic film with small tolerance.