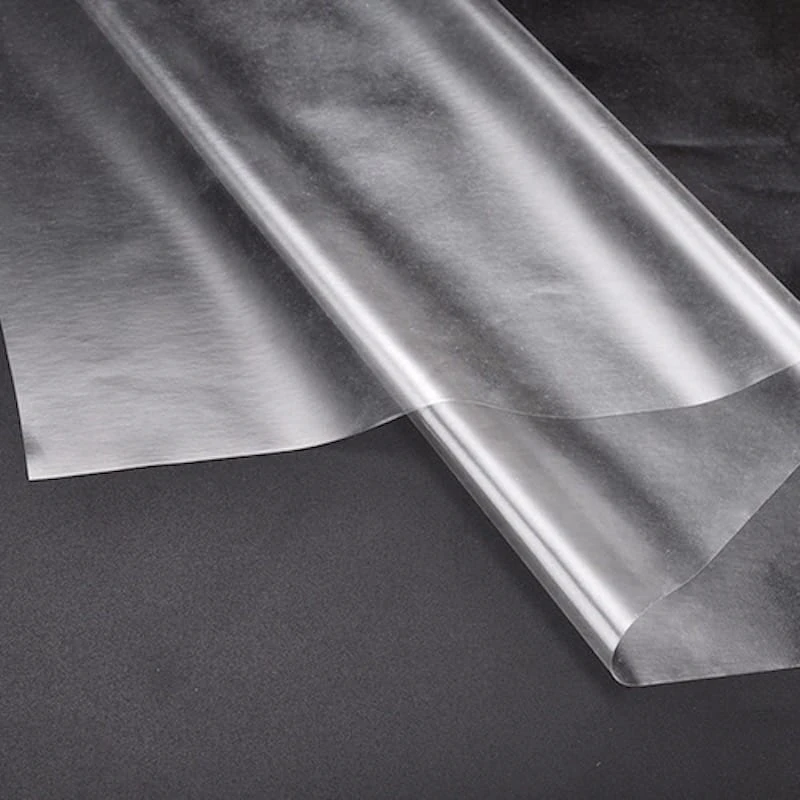

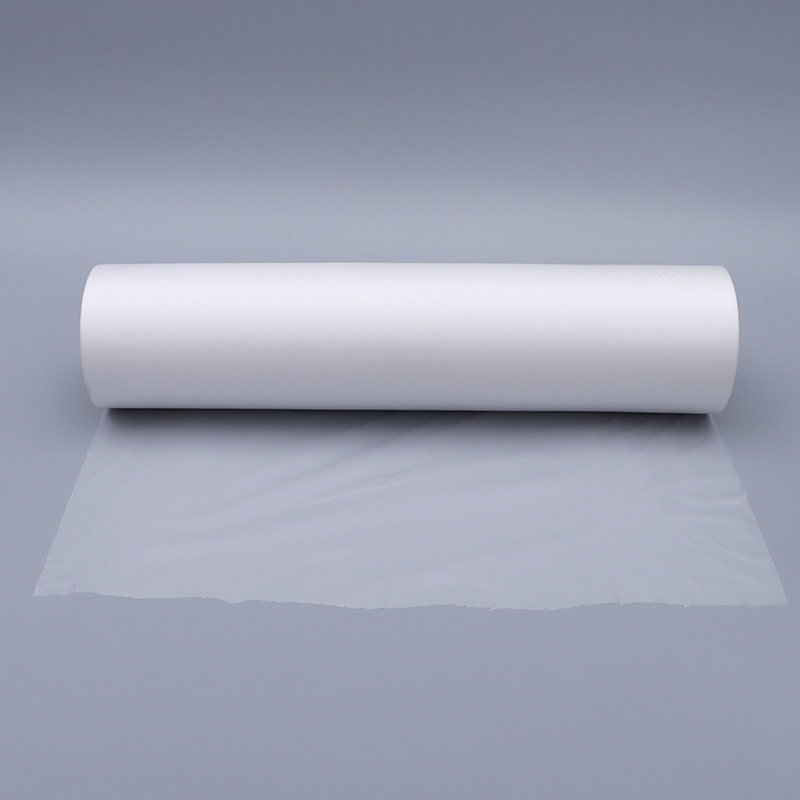

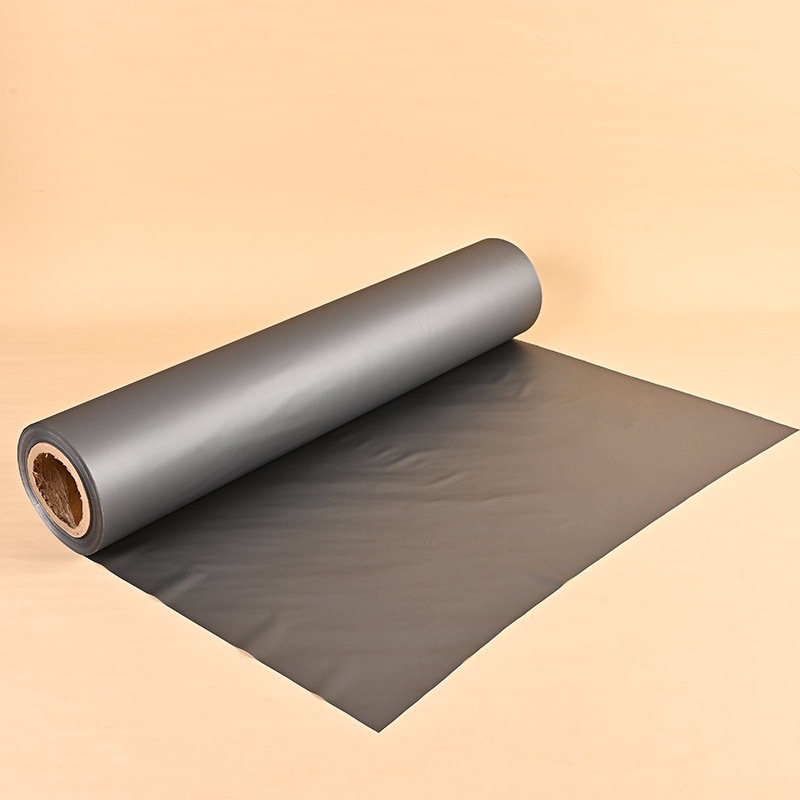

EVA hot melt adhesive film is made of ethylene-vinyl acetate copolymer as the main raw material. The English abbreviation of ethylene-vinyl acetate copolymer (ethylene-vinyl acetate copolymer) is EVA, which is formed by the copolymerization of ethylene and vinyl acetate, is an odorless, tasteless, non-toxic white or light yellow polymer.

The viscosity of EVA hot melt adhesive film is adjustable according to the performance requirements of adhesive. Due to the good compatibility of EVA, the addition of tackifier like petroleum resins, rosin resins will increase of the viscosity of EVA hot melt adhesive film. The addition of the paraffin will reduce the viscosity of EVA hot melt adhesive film.

The operating temperature of EVA hot melt adhesive film is generally between 80°C and 120°C, since relatively low melting point, the bonding process can be activated under low working temperature, which is highly saving the energy consumption.

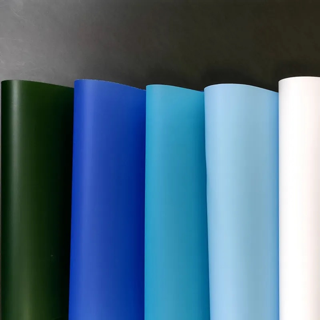

Due to these advantages, EVA hot melt adhesive film is widely used in material compounding and bonding in various industries. Such as shoe material compounding, luggage compounding, wall covering compounding. and automotive interior compounding, is deeply loved by the majority of users.