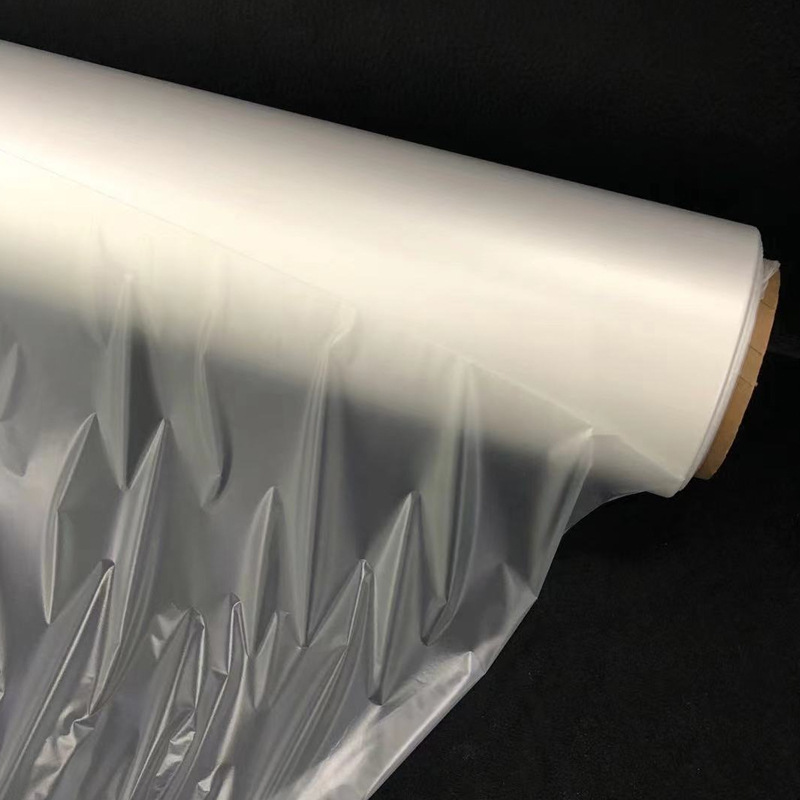

TPU film is a flexible film made of thermoplastic elastic particles. Due to the excellent elasticity and wear resistance, TPU film can be blister-processed into various shapes and sizes. The finished products process by blister thermoforming TPU film maintain the excellent feature of the TPU material, like environmental protection, non-toxicity, biocompatibility, no allergic reaction, no pyrogenicity, which are widely used in medical, toys, shoe material, military, sports, protective equipment, etc.

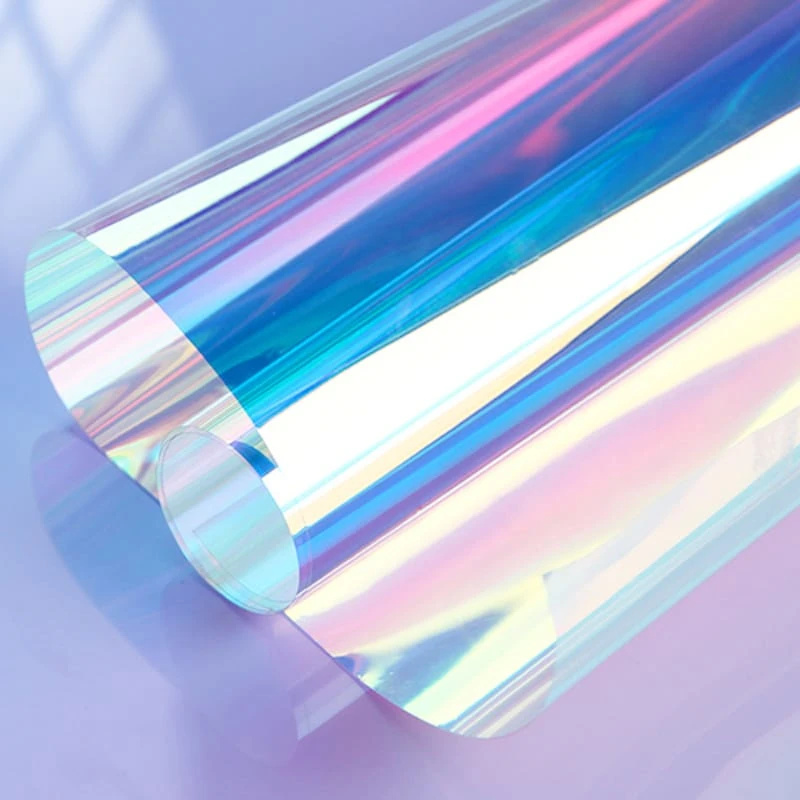

The thickness range of blister thermoforming TPU film from 0.05mm – 3mm, surface glossy, super transparent, translucent, or embossed with various leather textures to meet different production needs.

Blister Thermoforming TPU film are available in two different hardness types for different application.

1. Soft TPU film

Soft TPU film has a lower hardness, usually in the range of 10A-95A in the Shore A hardness table. Soft TPU film has high softness and elasticity, which is suitable for better stretch and bending properties applications.

2. Hard TPU film

Hard TPU film has a higher hardness, usually in the range of 55D-75D in the Shore D hardness table. Hard TPU film is relatively rigid, which is suitable for higher wear and scratch resistance applications.

The right hardness blister thermoforming TPU film ensures high wear resistance, high strength and chemical corrosion resistance, which greatly increase the value and service life of the blister finished product.

There are various processing methods for blister thermoforming TPU film, hot pressing, ultrasonic welding, sewing, laser cutting and other methods, which is easy operation.

In addition, blister thermoforming TPU film can be processed with high precision and is not easily deformed during the blister processing, which ensures the consistency and stability when blister-molding products of various shapes and sizes.

POLYSAN is professional plastic film China manufacturer, we produce and supply blister thermoforming TPU film comply with RoHS2.0 and REACH regulations, flame-retardant UL standards, and customized for different thickness, width, color, embossed texture, leather texture.