Hot melt adhesive film keeps solid at room temperature, melts and be sticky at high temperature. The types of hot melt adhesive film include bare film without release paper and film with release paper/release film.

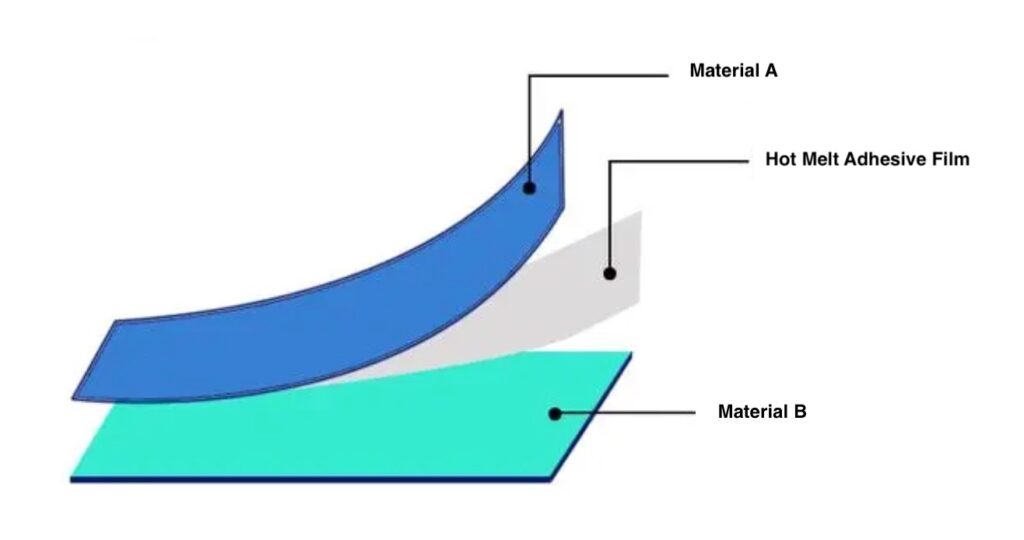

The hot melt adhesive film without release paper is a separate layer of glue film, which is easy operation. Place the hot melt adhesive film between the two layer of the bonded material, heat and laminate by pressing equipment.

The hot melt adhesive film with release paper is mainly for the operation of secondary lamination. Some tips of usage as below.

1. Align the glue side of the hot melt adhesive film with the bonded side of the material A, with the release paper facing up. The order of placement is: release paper layer/adhesive film layer/material A.

2. Heat the release paper side by low heating temperature, to ensure the adhesive film be sticky after melting.

3. Tear off the release paper.

4. Place the surface of the glued Material A with another piece of Material B in the order of: Material A/hot melt adhesive film layer/Material B, and then heat the equipment again for hot pressing.

The thicker of the hot melt adhesive film, higher the melting point and pressing temperature and time, to ensure the fully melting of the hot melt adhesive film and achieve the best adhesion with material.