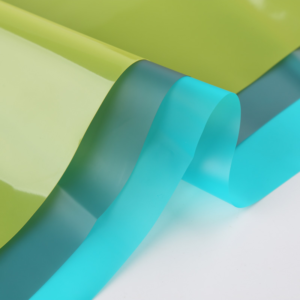

TPU foil is difficult to carry out separate blowing process as TPU foil has high extensibility and elasticity. The common process is to use easy-to-form PE carrier for co-extrusion processing with TPU foil. When using, the PE carrier layer will be peeled off and recycled when using, for environmental protection.

How to peel PE carrier from TPU foil ? It is very important to control the interlayer force between the TPU foil and the PE carrier layer.

If the interlayer force between the TPU foil and PE carrier is too large, the TPU foil will be prone to tension deformation after considerate peel force.

If the interlayer force between the TPU foil and PE carrier is too small, too easy to separate during traction, rewinding and other processes, which will be difficult to smooth when composite the TPU foil with other materials.

POLYSAN company have developed the adjustable interlayer force between TPU foil and PE carrier as 0.5 N/m ~20 N/m. POLYSAN company has more than 10 years production experience for plastic film, with enough serve and solution experience to each quality item of types of plastic film.