Polyethylene(PE) is a type of thermoplastic polymer with good flexibility, who is divided into high-density polyethylene (HDPE) and low-density polyethylene (LDPE) according to the polymerization method, molecular weight and chain structure, thus forming different plastic properties of LDPE and HDPE.

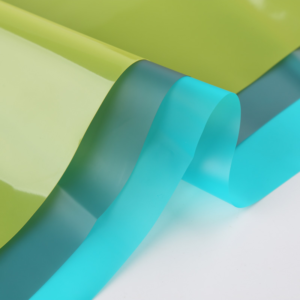

1. LDPE has good flexibility and stretchability, more transparent and better chemical resistance than HDPE.

2. HDPE has higher stiffness and strength, more resistant to wear and high temperature than LDPE.

3. Both LDPE and HDPE materials have good corrosion resistance, water resistance and heat insulation.

4. LDPE is usually used to make plastic bags, garbage bags, mulch, industrial packaging films, pharmaceutical and food packaging films, etc. HDPE is often used to make water pipes, chemical barrels, food containers, ligatures, ropes, Fibers for fishing nets and weaving, wires and cables, etc.

Both LDPE and HDPE plastic material are with good processing performance, who have good fluidity, low processing temperature, moderate viscosity, low decomposition temperature, and no easy decompose at a high temperature of 300°C in an inert gas.